Search This Supplers Products:steel wireAlloy Steel BarSteel TubeSpring Steel StripSteel Platespring steel wire

- Home

- About us

- Products

- Faqs

- Steelmaking

- Metal Forming

- Heat Treatment

- Metal Cutting

- Surface Treatment

- Company Policy

- Another Downstream Industry Technology

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Springs Industry

- Cutting Tool Industry

- Tool Steel

- High Speed Steel

- Drill Tool Industry

- Oil and Gas

- Boiler Industry

- Bearing Industry

- Auto Parts Industry

- Fasteners Industry

- Experiment Ways

- Nickel Based Alloy

- News

- Certificate

- Contact us

AISI 4137H Hollow Bar

- group name

- Hollow Bars

- Min Order

- 1 metric ton

- brand name

- fushun

- model

- AISI 4137H

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Mon, 26 Dec 2022 15:50:55 GMT

Paramtents

Heat treatment Quenching and Tempering

Surface Bright or Black Surface

Application Oil industry, Raise bore drill rods and drive subs

Standard AMS 6427 AMS 6359 AMS6304 ASTM A646

Packging & Delivery

-

Min Order1 metric ton

Briefing

Detailed

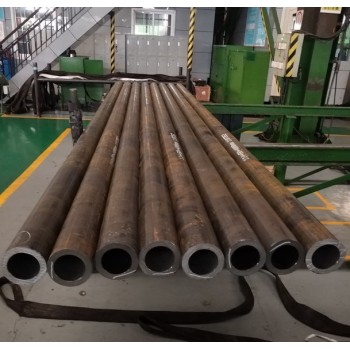

AISI 4137H Hollow Bar

4137H Hollow Bar offers good strength, weldability, impact and abrasion resistance while also being easy to machine. Because it's stronger than carbon steel, thinner-walled tubing can be used for the same purpose. 4137H tubing stock is available in full size and custom cut lengths.

Advantages

Excellent strength-to-weight ratio

High tensile strength, ductility, and toughness

Lighter and more robust than carbon steel

Easy to weld, form, and machine

Ability to harden using heat-treating or work hardening

SIZE RANGE

OD : 1.250” – 31.250”

OD Tolerance: +/- .005” (up to 1.500” OD), to +/- .010” (above 1.500” OD)

Wall thickness : 0.100”– 3.150”

Wall Tolerance: +/- 10% (For ID Over .500”) to +/- 15% (for ID under .500”)

17.000” - 24.000” random lengths (Cut to Length available)

Chemical Composition %

Grade | C | Mn | Si | P | S | Cr | Mo |

4137H | 0.34-0.41 | 0.60-1.00 | 0.15-0.35 | 0.035 max | 0.040 max | 0.75-1.20 | 0.15-0.25 |

MANUFACTURING PROCESS

Depending on the grade and type, alloy tubing is either produced per ASTM A519 or API 5CT industry standards. See CDS, HRS, or Boring manufacturing processes per the specific type and specification for more information.

1 CDS: seamless tube and pipe is produced by piercing hot billets and subsequent rolling which reduces their diameter and elongates them. This material is then passed through a die and over a mandrel plug to produce an accurate size and gauge which is the essence of the cold drawing process.

2 HRS: Hot rolled mechanical tubing is produced by heating a solid billet or bar and then rotary piercing it as it rotates on rollers. Then the final processing through multiple pass size-reducing mills occurs. Tolerances and finish are similar to other hot worked steel products. Range of sizes and grades are more restricted than cold finished by the nature of the process involved.

3 Forging + Boring/Drilling: Drilling is the process of removing material by using a drill bit. Drill bit is a long, sharp instrument, often with flutes, but it may have a variety of features depending on the work.

Applications

Aerospace applications

Gas and oil equipment

Order 4137H Hollow Bar Today

We stocks a wide range of 4137H hollow bar sizes for your specific project needs. We offer quick delivery. Contact us today to discuss using round 4137H hollow bar in your application.