Search This Supplers Products:steel wireAlloy Steel BarSteel TubeSpring Steel StripSteel Platespring steel wire

- Home

- About us

- Products

- Faqs

- Steelmaking

- Metal Forming

- Heat Treatment

- Metal Cutting

- Surface Treatment

- Company Policy

- Another Downstream Industry Technology

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Springs Industry

- Cutting Tool Industry

- Tool Steel

- High Speed Steel

- Drill Tool Industry

- Oil and Gas

- Boiler Industry

- Bearing Industry

- Auto Parts Industry

- Fasteners Industry

- Experiment Ways

- Nickel Based Alloy

- News

- Certificate

- Contact us

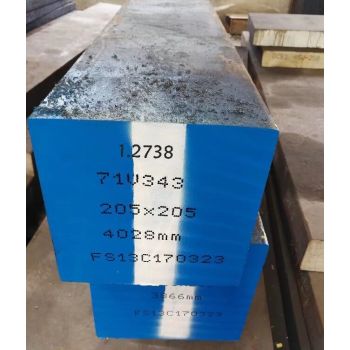

1.2738 P20 40CrMnNiMo8-6-4 2738 Plastic Mould Steel Plate

- group name

- Plastic Mould Steel Plate

- Min Order

- 1 piece

- brand name

- fushun

- model

- 1.2738

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Thu, 14 Oct 2021 14:28:22 GMT

Paramtents

Surface condition Black, Machined

Delivery conditon Hot rolled, Cold rolled

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Introduction:

1.2738 Pre-hardened Plastic Mould Steel, hardness in as-delivered condition 280 to 325 HB. Good machinability, suitable for texturing, improved through hardening in comparison to 1.2311, good polishability.

Applications:

Large plastic moulds with deep engravings and intensive impacts on the core. 1.2738 Pre-hardened Plastic Mold Steel is the logical development of 1.2311, a pre-hardened plastic mould steel for use in large moulds, which also have to display high core strength. The additional nickel content of 1 % increases through hardening. 1.2738 is a micro-alloyed, vacuum-degassed steel with the following excellent features: good machinability, outstanding polishability, good texturing properties.

Chemical Composition(%):

Grade | C | Si | Mn | p | S | Cr | Ni | Mo |

1.2738 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.030 max | 0.030 max | 1.80-2.10 | 0.90-1.20 | 0.15-0.25 |

Product Details:

Quality Standard: GB, ASTM

Similar Grade: 1.2738 P20+Ni 718

Size Range:Thickness1-3.5mm Width:800mm

Surface Condition: Bright

Delivery condition: Cold rolled only

Heat Treatment :

Annealing: Annealing temperature: 710 ~ 740 °C, holding time is decided by the thickness of the DIN 1.2738 die steel, one hour per 25mm. Colding in furnace after thermal insulation.

Destressing: Heating temperature: 600 °C (annealed condition), 550 °C (quenching and tempering state), holding time is decided by the thickness of the 1.2738 steel, one hour per 50mm. Colding infurnace after thermal insulation.

Quenching and tempering:

Preheating temperature 500 ~ 600 °C, quenching temperature 840 ~ 880 °C, holding 30min (the mold have to quenching in the protective gas to prevent oxidation and decarbonization). Oil cooling, cooling to 50 ~ 70 °C,immediately tempered. Tempering holding time is decided by the thickness of the 1.2738 steel mould, one hour per 25mm, at least 2h. Tempering temperature: 180 °C / 200 °C / 300 °C / 400 °C / 500 °C / 600 °C, the hardness: 52HRC / 51HRC / 48 HRC / 46HRC / 42HRC / 34HRC.