Search This Supplers Products:steel wireAlloy Steel BarSteel TubeSpring Steel StripSteel Platespring steel wire

- Home

- About us

- Products

- Faqs

- Steelmaking

- Metal Forming

- Heat Treatment

- Metal Cutting

- Surface Treatment

- Company Policy

- Another Downstream Industry Technology

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Springs Industry

- Cutting Tool Industry

- Tool Steel

- High Speed Steel

- Drill Tool Industry

- Oil and Gas

- Boiler Industry

- Bearing Industry

- Auto Parts Industry

- Fasteners Industry

- Experiment Ways

- Nickel Based Alloy

- News

- Certificate

- Contact us

What is the relationship between hardness and tensile strength?

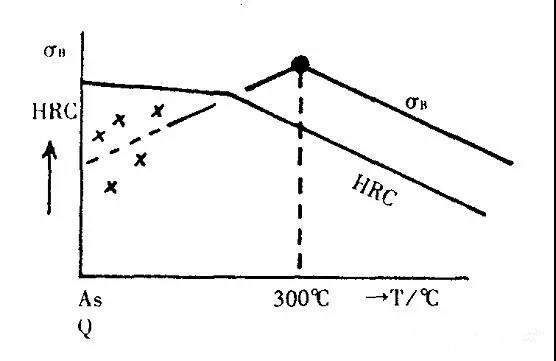

When the hardness of the steel is below 500 HB, the tensile strength is proportional to the hardness, kg/mm2(óB)=1/3 X HB=3.2 X HRC=2.1 X HS, but the above relation is not in any case. Established, from the aspect of heat treatment, when the tempering temperature is low, the correlation between kg/mm2 and HRC may be destroyed. The relationship between tempering temperature, hardness and tensile strength of steel is shown in the figure.

From this figure, it can be seen that the hardness decreases with the increase of the tempering temperature, but the relationship between the hardness and the tensile strength is hardly established in the quenched state and tempering at a temperature of 300° C. or lower. When the tempering temperature is around 300°C, there is a correlation between kg/mm2 and HRC, that is, the hardness is high, the tensile strength is high, the hardness is low, and the tensile strength is low. It is difficult to find the value of kg/mm2 in the low temperature tempering state because the distribution of the tensile strength values is very discrete.

Since the temperature/kg2 of the low-temperature tempering material is unstable, it cannot be determined. Therefore, in the Japanese Industrial Standards (JIS), the tensile properties of the temperature tempering material of 400°C or higher (also tempered workpieces of 300°C) are also tested. In other words, the tensile test was performed only on the tempered parts (quenched +400°C tempered). Industrially, the use of low-temperature tempering parts is only required when anti-rotational bending fatigue and wear resistance are required. High frequency quenching and carburizing quenching are examples of this application. Tensile stress parts do not use low temperature tempering. However, in low-carbon steels, quenching M can be self-tempered (so the Ms point is high), and there are also users in the quenched state. The low-carbon steel lath martensite structure is self-tempered and can be applied industrially. However, the hardenability and mass effect must be considered at this time (if necessary, B, Cr, Mn, and other metal elements should be added).